"我们努力解决因维护失误而反复出现的模具问题,结果在六个月内将非质量成本降低了 9%。"

-财富》美国 500 强领先汽车公司首席执行官说明

一家汽车行业的领先企业面临着巨大的挑战,因为其与供应商之间的业务需要更加清晰,从而导致效率低下和生产延误。为解决这一问题,该公司与 行业专家 部署先进的 人工智能驱动的工具数字化系统 以改进监督工作,并根据数据更快地做出决策。早期成果表明,运营效率显著提高,包括意外停产减少,总体产量增加 8%。这些效率的提高减少了生产时间的损失,并产生了连锁效应,从而提高了产品质量,加快了产品上市速度。

主动转向人工智能工具管理

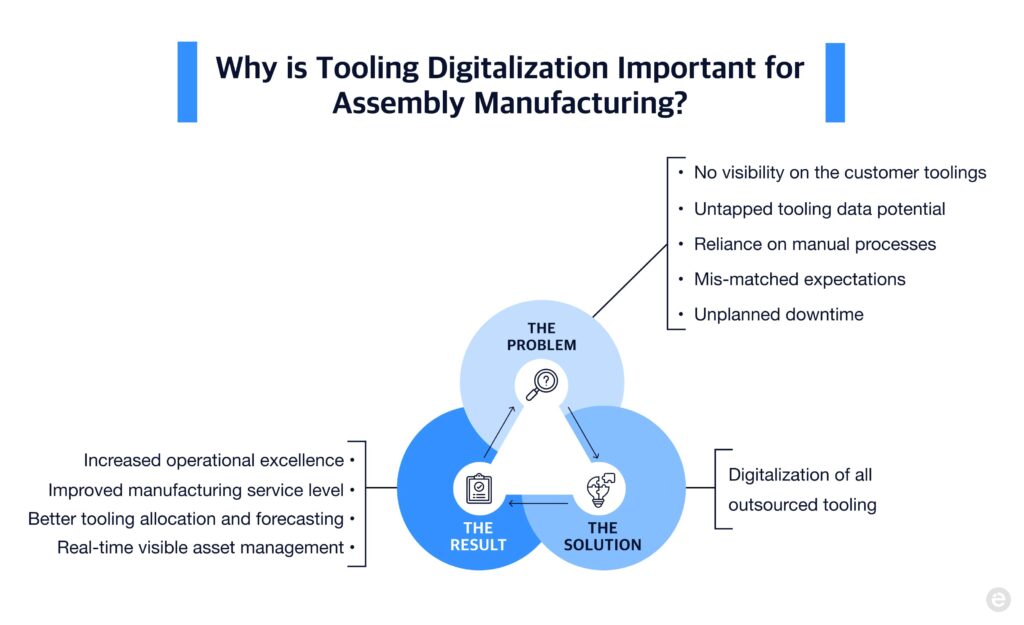

旨在提高运营效率和产品质量的装配制造商向人工智能(AI)寻求解决方案。通过利用人工智能,他们可以对生产流程获得无与伦比的洞察力,从而做出更明智的决策,并积极应对维护和生产方面的挑战。

可见度差距

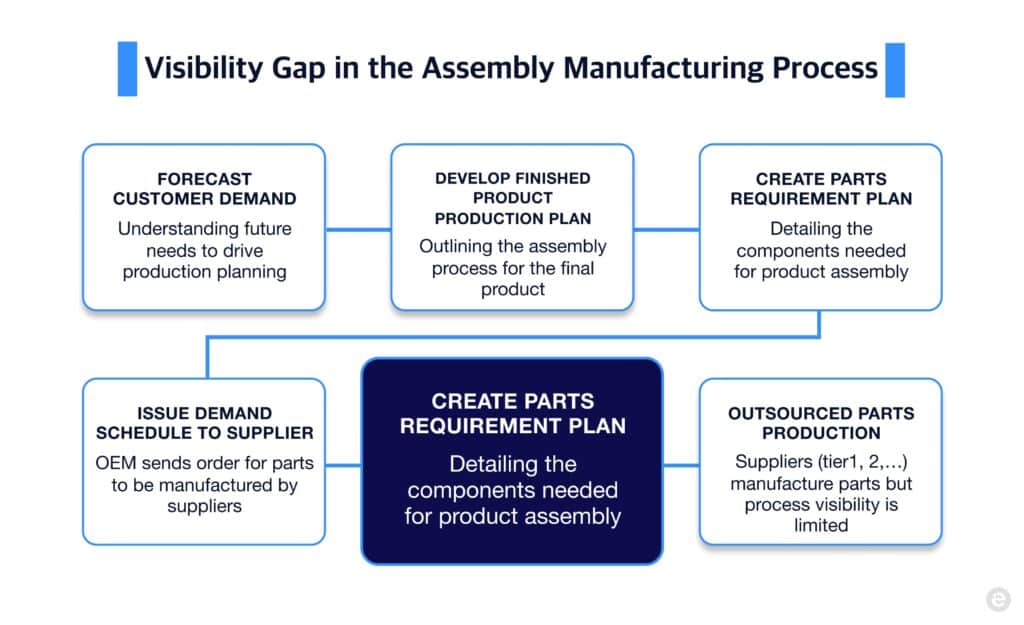

准确预测客户需求对于制定战略生产计划、确保及时组装和采购组装生产所需的零部件至关重要。然而,如果在订购部件和开始生产之间缺乏清晰的洞察力,就会延误流程,限制原始设备制造商(OEM)的灵活性,使其迅速适应市场变化的能力受到挑战。解决这一问题对于提高效率和管理人员的适应能力至关重要。

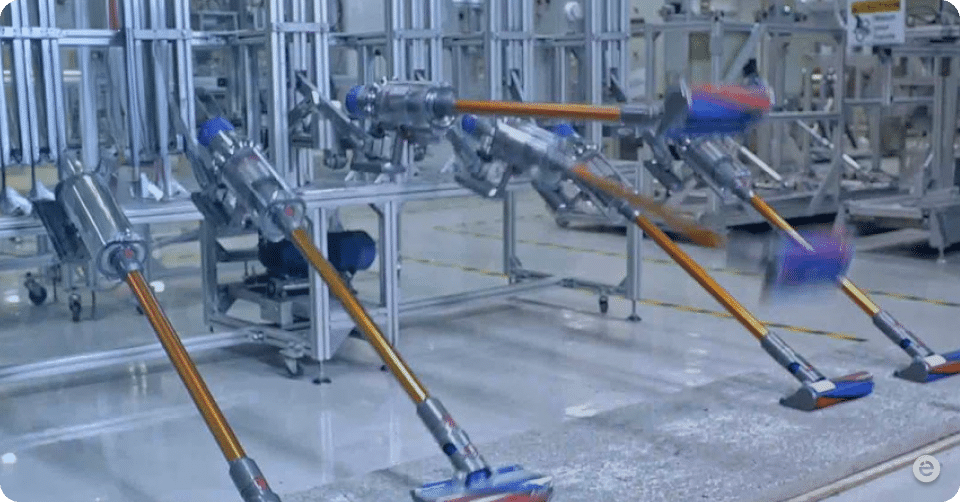

数字技术的进步,尤其是工具数字化,为解决制造过程中的可视性差距提供了解决方案。这项技术改变了原始设备制造商的运营方式,从传统方法过渡到更加灵活、透明和快速响应的框架。

外包制造的这一战略进步如何重新定义原始设备制造商的运营格局?

在外包制造中引入数字化增强功能可提高效率,并改变原始设备制造商与供应商的合作方式。从手动系统转向带有物联网传感器和数据分析功能的智能平台,可即时获取关键信息,实时洞察生产流程和部件质量。

解决供应链不透明问题

供应链的可见性对于提高效率和降低成本至关重要。获取实时数据对于进行彻底的根本原因分析和确保竞争优势至关重要。缺乏此类数据会导致生产延误和成本上升。

下面是我们客户的一个使用案例:

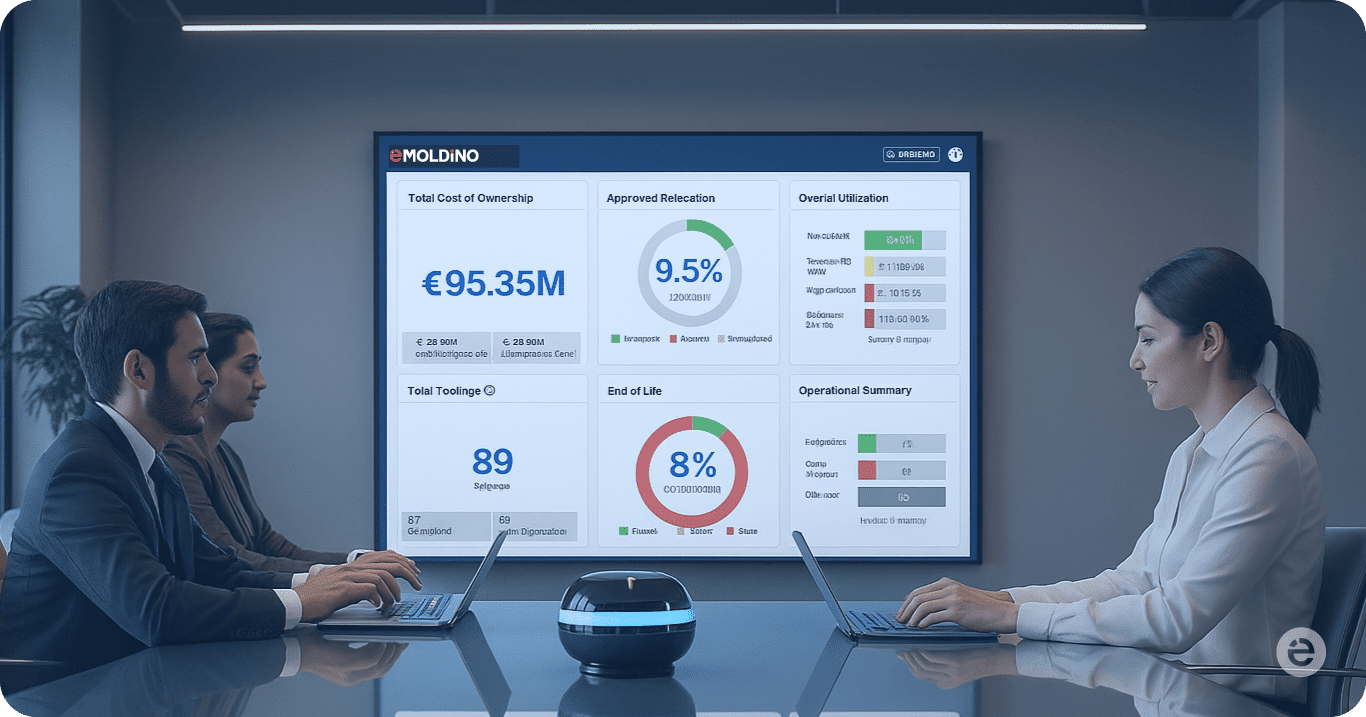

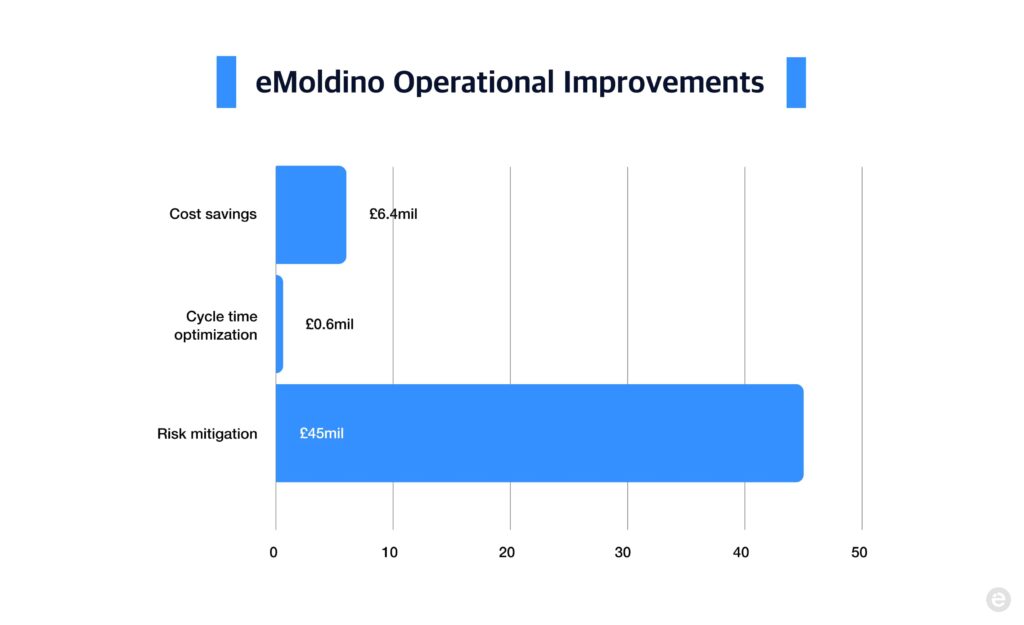

一家全球领先的汽车公司因供应商产能问题而面临巨大损失,于是向行业专家寻求解决方案。该模具管理系统试点项目确定了大约 5 200 万英镑的潜在运营改进这为收入的大幅增长铺平了道路,具体细分如下 成本节约:640 万英镑 周期时间优化:60 万英镑 风险缓解:4500 万英镑。 这一战略合作伙伴关系提高了供应链的透明度,实现了对生产、模具寿命和供应商绩效的主动管理。其结果是节省了大量成本,并增强了竞争力。这个案例充分体现了数字化模具解决方案对汽车行业的影响。

"工具管理系统试点项目确定了约 5 200 万英镑的潜在运营改进"。

总结

在汽车行业,采用工具数字化和人工智能可以重新定义竞争优势和收入模式。

贵公司是否已准备好利用这些先进技术来促进收入增长并在行业内建立新的基准?

关于作者

eMoldino

eMoldino

eMoldino 致力于数字化、简化和改造您的制造和供应链运营。我们帮助全球制造商推动企业创新,同时保持协作和可持续发展的核心价值。 请与我们联系,了解更多信息 →

您喜欢阅读这篇文章吗?

4 /5.计票: 3

浏览我们的最新文章