导言

在外包生产中、 管理废品率对保持盈利能力和运营效率至关重要.高废品率会增加成本,凸显效率低下,从而影响产品质量、生产能力和盈利能力。数字技术如何在降低废品率、提高运营能见度和生产效率方面发挥关键作用?

工具数字化在减少废品中的作用

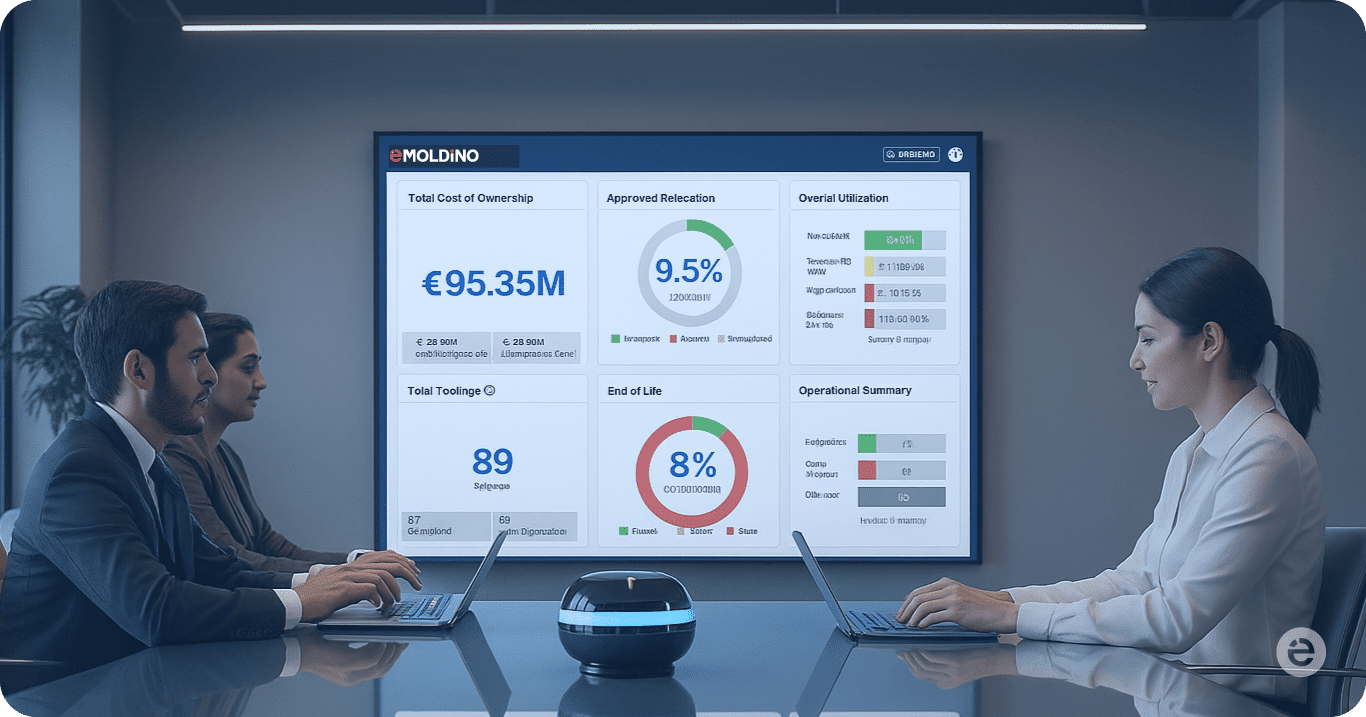

eMoldino 的物联网传感器可对生产工具进行实时监控和调整,从而发挥关键作用。这减少了生产过程中的可变性,并将缺陷降至最低。数字化转型提高 决策, 简化生产并支持 竞争力 通过战略技术集成,降低成本。据麦肯锡公司称,通过缓解生产瓶颈和提高整体流程效率,这种整合每月可降低 5% 至 7% 的成本。(麦肯锡公司).

典型案例

2022 年 5 月,一家领先的汽车公司与工具数字化专家共同启动了一个试点项目,目标是 生产效率低下 两家主要供应商。重点是高压铝压铸(HPDC)--这是对其生产至关重要的一道工序,但却存在废品率高和操作差异的问题。

在惠普公司,对模具预热温度的监控不足导致废品率过高、生产成本上升和产能损失。核心挑战包括

- 工具数据不足: 这意味着模具磨损和即将发生故障的早期迹象没有被发现。

- 低能见度: 在实时监控生产方面存在很大差距,因此很难确定操作是否偏离了设定参数。

- 根源分析: 缺乏详细的业务可视性阻碍了有效诊断和解决效率低下根本原因的能力。

为了应对这些挑战,这家汽车公司采用了先进的工具数字化解决方案,该方案配备了专门的传感器,可监测工具的外部温度,有效跟踪预热时间和温度偏差,从而提供:

- 增强工具效率可见性: 有关工具性能的实时数据有助于确定效率损失和潜在的改进措施。

- 能力和质量监测: 对生产能力和零件质量的持续监控确保了对偏差的及时发现和纠正,从而降低了报废的可能性。

- 数据驱动的洞察力: 综合工具数据分析的集成有助于进行主动维护和操作调整,从而减少停机时间并提高产出质量。

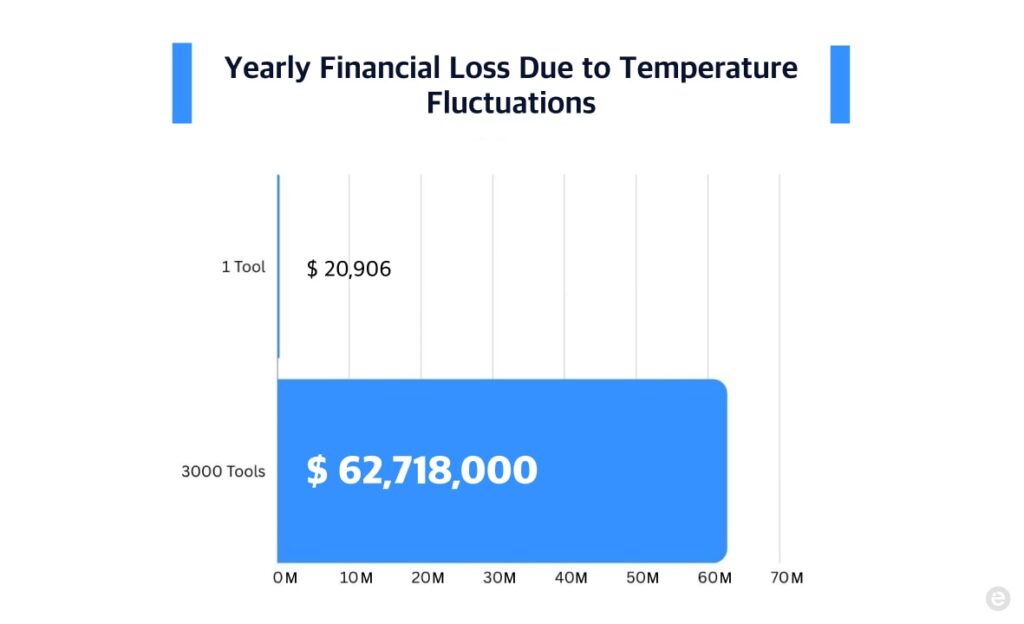

实施先进的工具数字化解决方案后发现,每天的温度波动会导致每天损失 5 分钟的生产时间。虽然这些波动只占 0.3% 在生产周期中,他们生产了 4,181 个有缺陷的部件 每个工具每年从 1,200,000 个部件.在财务上,这意味着巨大的成本,每个缺陷部件的成本为 $5,累计达 $ 每个工具损失 20 906 美元 每年因零件缺陷而造成的损失。在 3,000 件工具中,这一问题导致每年损失共计 $62,718,000.

通过减少浪费,试点项目节省了大量成本,并提高了实时数据监控在简化生产流程方面的价值。

结论

具有前瞻性思维的制造业领导者不仅将废品率和流程效率低下视为需要克服的障碍,还将这些挑战视为大幅提升和实现战略差异化的机遇。具有远见卓识的公司不会简单地缓解效率低下的问题,而是会利用这些时机实施深刻的数字化转型。贵公司是否已准备好接受工具数字化和实时数据分析,以增强其运营复原力?

关于作者

eMoldino

eMoldino

eMoldino 致力于数字化、简化和改造您的制造和供应链运营。我们帮助全球制造商推动企业创新,同时保持协作和可持续发展的核心价值。 请与我们联系,了解更多信息 →

您喜欢阅读这篇文章吗?

4 /5.计票: 1

浏览我们的最新文章