"供应商延迟交付零件经常会导致成本增加,特别是在我们的汽车行业,往往需要加快装运,以满足最后期限的要求"。

- 全球汽车供应商。

"我们最近经历了供应中断,导致临时停产"

- 汽车行业的领导者。

问题的根源是什么?

问题的核心很简单:

尽管许多汽车制造商已在其业务领域的数字化转型方面取得了长足进步,但大多数汽车制造商尚未完全掌握专业技术。

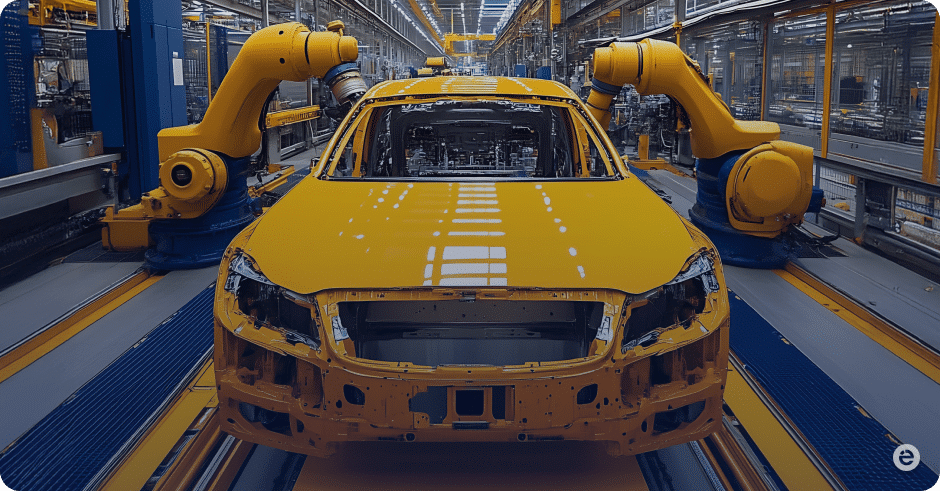

根本问题是需要 全面采用技术 在整个行业中,压铸等关键阶段的信息严重脱节。这种脱节会导致交货延误、供应商风险和经济损失。企业高管通常会考虑购买额外的模具或分散供应商,以应对短缺并确保质量。由于停机和达不到生产目标会带来高昂的成本,因此清晰了解生产数据变得至关重要。

解决方案如 实时容量规划 这些工具已显示出良好的前景,成功实施后可节省大量成本并改善运行状况。

"我们面临着产能问题,需要从可靠的来源获得实时的供应商产能信息。以前,我们依赖的是可能被篡改的数据。实时透明度对战略决策至关重要。供应商通过 Excel 提供手动数据,这需要通过先进技术与实时数据进行验证。

- 全球汽车制造商。

价值

行政领导者认识到简化运营、节约成本和增加收入机会的价值。技术创新(如传感器集成)对于提高供应链效率和减少延误至关重要,可显著节省成本并改善客户关系。

客户使用案例

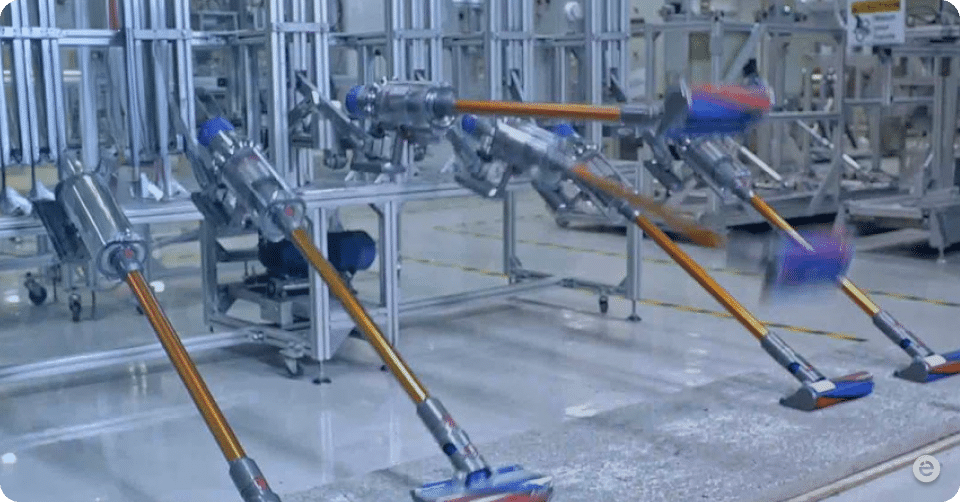

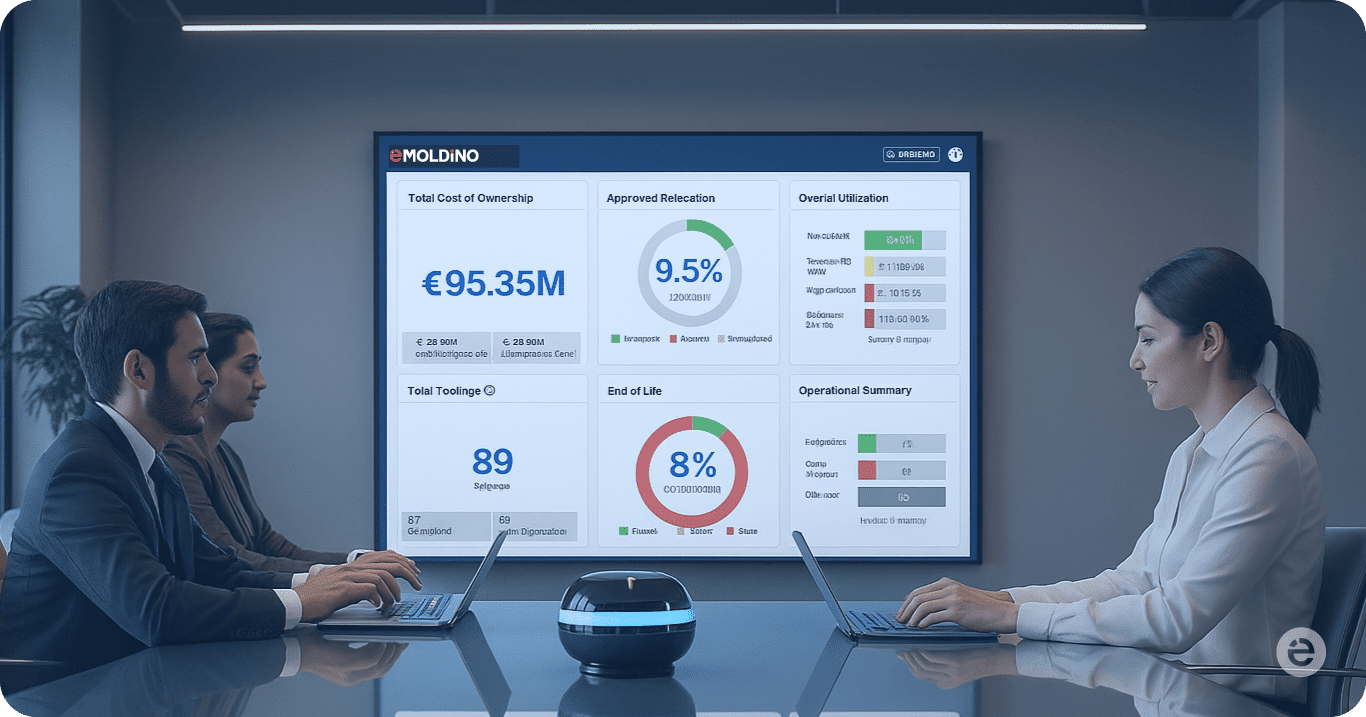

一家汽车供应商需要更实时地了解模具产能。这一需求源于供应商经常错过交货期限,迫使公司承担额外成本。为了遵守生产时限,通过空运(汽车行业特别普遍的一种解决方案)来加快材料的交付成为一种常规做法。他们在所有工具中安装了传感器,以便更好地将供应链与需求规划结合起来。这一战略性举措减少了延迟交货和意外的工具故障,为公司节省了 $.2525 亿美元。

另一家汽车巨头面临的挑战是,没有足够的生产产量实时数据和可用的替代供应商或生产基地。这种信息差距导致了频繁的延迟交付和及时供应部件的短缺。采用工具数字化解决方案后,该公司能够有效管理产能并降低交付风险。通过采用传感器监控生产和识别备用供应链,该公司节省了 19.6 万欧元。这些实例凸显了利用技术提高成本效益和运营产出的重要性。

结论

许多汽车公司注意到,由于劳动力问题或公共危机等因素,依赖单一来源供应商有可能导致供应中断,从而对生产和财务状况造成潜在影响。

管理人员如何降低这些风险并确保生产的连续性?

关于作者

eMoldino

eMoldino

eMoldino 致力于数字化、简化和改造您的制造和供应链运营。我们帮助全球制造商推动企业创新,同时保持协作和可持续发展的核心价值。 请与我们联系,了解更多信息 →

您喜欢阅读这篇文章吗?

4.4 /5.计票: 5

浏览我们的最新文章