AI has changed supplier negotiation practices and helped companies save money like never before. Our team has seen how artificial intelligence turns traditional procurement methods into strategic advantages based on data. A recent case study showed that AI-powered negotiation techniques helped cut costs by 40%.

Companies used to face challenges with supplier performance tracking. AI now brings connected intelligence throughout the supplier lifecycle and makes our negotiation process better. Our team used AI-driven analytics to move from reactive contract negotiations to proactive management through prescriptive analytics. The technology has made our negotiation skills stronger by providing applicable information and streamlining complex review processes.

This case study demonstrates how predictive analytics helped forecast supplier performance and potential risks that led to smarter decisions and lower costs. We found that AI-driven tools could analyze supplier metrics using historical data, which made our supplier partnerships more data-informed. The advanced technologies helped us improve supplier selection and performance management substantially. We tapped into considerable value for our procurement team.

Understanding the Supplier Negotiation Process Before AI

Supplier negotiation used to be more art than science. It relied on personal expertise and relationship management. Before AI came along, procurement teams faced many roadblocks that kept them from getting the best deals. They struggled with manual work, missing information, and mostly played catch-up when dealing with suppliers.

Manual contract review and pricing analysis

Teams had to review contracts by hand before AI solutions arrived. They spent days or weeks going through long documents line by line. Most organizations used up to 70% of their time just handling routine contract work instead of planning better deals.

People interpreted contracts differently, which led to mistakes and missed details. Price analysis depended on old data and personal judgment. Teams kept track of supplier prices in spreadsheets or simple databases that couldn’t do much analysis.

“It’s like we were trying to piece together a puzzle without seeing the full picture,” notes a veteran procurement manager. “We’d analyze previous contracts, but without comprehensive market data, our pricing benchmarks were often incomplete.”

Teams gathered data from old contracts, purchase orders, invoices, and market reports by hand. This method often left gaps in information. Without tools to compare supplier terms across categories, companies couldn’t use insights from one supplier to get better deals with others.

Limited supplier performance visibility

Traditional supplier management lacked a clear view of how suppliers performed. Companies tracked simple things like delivery times and defect rates, but collecting this data took lots of work. Teams only checked performance every few months or yearly instead of getting live updates.

Research shows that poor suppliers cause more frequent and longer disruptions. The combination of frequency and duration makes their negative effects worse. Yet many teams couldn’t spot these patterns until problems got big because they lacked good monitoring systems.

Supplier performance data stayed scattered across departments and systems. Procurement watched deliveries, quality control counted defects, and finance handled payments. This split made it impossible to see the whole picture of supplier relationships. Negotiators walked into meetings without knowing enough about supplier reliability, quality, and value.

Teams also lacked standard ways to evaluate suppliers. Different people used different criteria, which made comparing suppliers or tracking improvements hard. This inconsistency made it tough to prepare for negotiations and develop strategies.

Reactive negotiation strategies

The biggest weakness of old-school supplier negotiation was its reactive nature. Teams only negotiated when contracts needed renewal or problems came up. They missed chances to spot improvements or fix issues early.

This reactive approach hurt organizations in several ways:

Limited leverage: Suppliers had the upper hand when negotiations only happened after problems arose

Time pressure: Rush negotiations left little time to research, look at options, or plan well

Focus on immediate issues: Quick fixes often trumped long-term planning

Success in negotiations varied based on who led them because teams relied on personal skills rather than data. Companies lost valuable knowledge about what worked when key people left.

Negotiations with smaller suppliers often came down to yes or no choices instead of finding creative solutions that could help both sides. This confrontational approach damaged relationships and stopped partnerships from growing.

The old way of negotiating with suppliers wasted time on manual work, lacked visibility, and mostly reacted to problems. These limits not only slowed things down but also led to higher prices, worse terms, and missed partnership opportunities. Without good performance data, organizations couldn’t tell their best suppliers from their worst during negotiations. This weakness hurt their bargaining power and stopped them from creating more value.

AI Tools Used in the Case Study

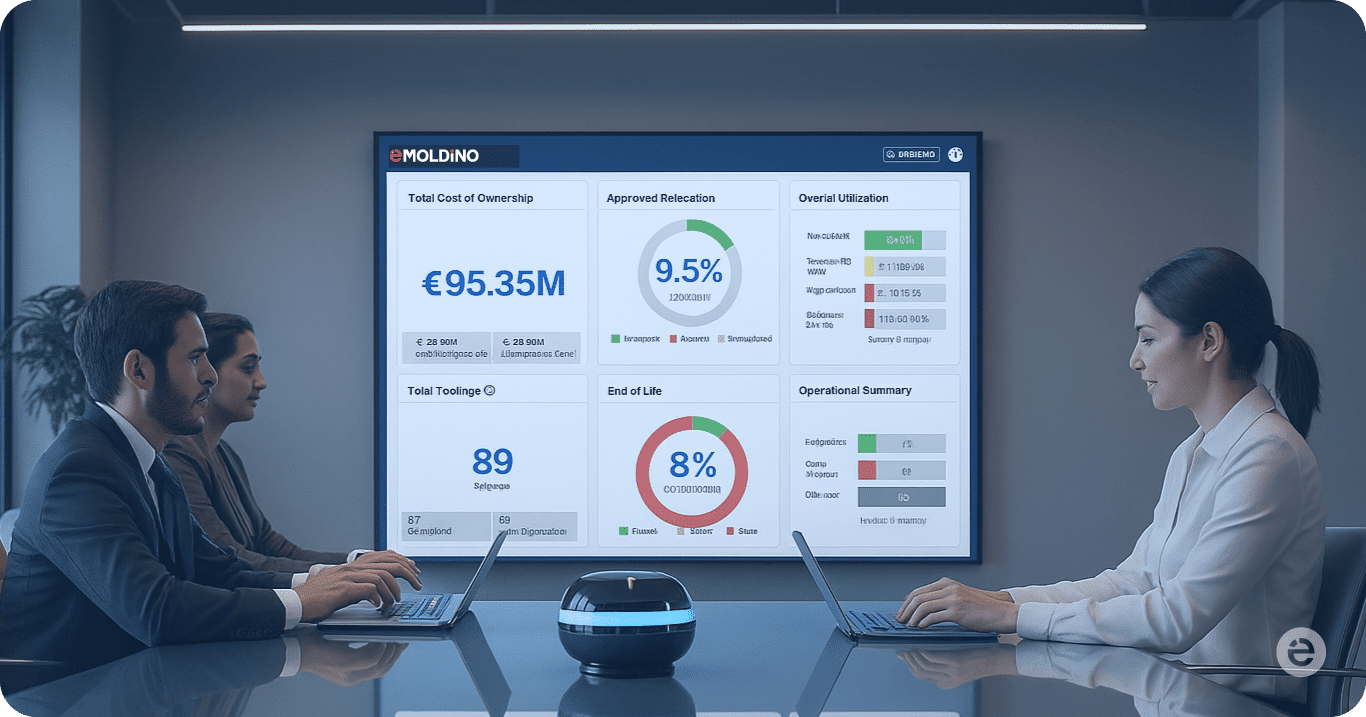

We transformed our supplier negotiations by implementing three AI technologies that worked together to deliver amazing results. Each solution fixed specific problems in traditional supplier negotiations and created a smart system that changed how we handle procurement.

Contract intelligence using NLP

Our AI-powered supplier negotiation strategy started with contract intelligence technology powered by Natural Language Processing (NLP). This smart tool changed how we analyze contracts by automatically pulling key information from thousands of supplier agreements.

The system also spots potential risks in agreements by comparing contract clauses with standard templates. This helps legal teams quickly spot differences from standard terms. The results are impressive – legal teams now review contracts 60% faster and with less effort.

Predictive analytics for supplier behavior

The next step was adding predictive analytics tools to forecast how suppliers might perform and behave. This technology helped us move from reacting to problems to preventing them.

The system looks at past supplier data, market trends, and world events to predict possible disruptions. By analyzing performance data, delivery times, quality issues, and other factors, the AI model spots patterns that show which suppliers might have problems or supply shortages.

The predictive analytics part uses regression analysis, time series analysis, and clustering to understand how different factors relate and change over time. These methods help build models that can predict future scenarios based on past data.

Dynamic pricing analysis is one of the most valuable features. The AI studies pricing data from past quotes, market trends, and competitor prices to suggest the best pricing strategies. Our procurement team now negotiates better deals because they understand supplier margins and negotiation ranges.

Automated negotiation bots for RFx processes

The final piece of our AI system includes automated negotiation bots designed for RFx processes. These smart agents make supplier selection and negotiation much easier.

The autonomous platform runs thousands of negotiations with suppliers at once. This finds better deals for everyone while saving millions and keeping suppliers happy. The system uses natural language processing to pull key information from RFx documents and vendor quotes, which makes comparison and evaluation faster.

These bots excel in three main areas:

-

Automated supplier identification – The AI studies past data, market trends, and vendor performance to find and suggest the right suppliers for RFx requirements.

-

Proposal evaluation – AI algorithms review vendor responses and compare them to our criteria to find strengths, weaknesses, and areas that need more review.

-

Negotiation automation – The most advanced feature lets bots negotiate directly with suppliers through a chat interface, following rules set by our procurement team.

Suppliers love negotiating with the AI – about 90% said they had a great experience in follow-up surveys. One supplier said, “This was the easiest negotiation they’ve ever had,” which shows how the technology makes things better for everyone involved.

How AI Improved Supplier Negotiation Strategy

AI completely changed how we handle supplier negotiations. We moved from gut feelings to an evidence-based process. Our procurement team learned new things about supplier relationships and negotiations through advanced analytics and machine learning.

Evidence-based supplier grouping for negotiation tiers

Our AI-driven approach started by grouping vendors based on multiple factors beyond the usual metrics. This classification helped us place suppliers in strategic tiers that needed different negotiation styles.

The AI looked at over 60 data points for each supplier and created detailed profiles that showed hidden patterns in performance and risk factors. We built a systematic framework instead of trusting instincts. The framework looked at:

Strategic importance and spend volume

Performance history and reliability metrics

Risk profile and market position

Innovation potential and collaborative history

This grouping helped us create custom negotiation tactics. We focused on long-term value creation with strategic suppliers. With commodity suppliers, we pushed for competitive bidding and cost savings. This targeted approach led to better negotiations with all suppliers.

Market intelligence in real-time for better pricing

The biggest improvement came when we added real-time market data to our negotiation prep. Our AI system gave detailed market analysis before supplier meetings, which gave our team an edge.

Our system tracked commodity indices, supply-demand patterns, and competitor pricing. We could challenge suppliers’ market claims with real data. This insight changed us from reactive to proactive negotiators. To name just one example, when suppliers said they needed price increases due to market conditions, we could check these claims against current data.

We could link commodity price changes to product margins through materials analysis. Our team knew exactly how changing commodity prices should affect supplier costs, which led to smarter negotiations.

Companies that use similar AI market intelligence systems save 10-20% through better deals and lower costs. The system’s predictive capabilities helped us spot price changes early, so we could time our negotiations better.

Contract term modeling

AI-powered scenario modeling became our third major upgrade. Our team could test multiple contract scenarios to find the best terms instead of aiming for one target.

The system used past data and AI to create different contract models with various terms, pricing, volume commitments, and risk sharing. We assessed each scenario’s financial impact, risk, and fit with our goals.

This helped most with complex negotiations that had many moving parts. The AI checked thousands of possible combinations and found opportunities humans might miss. Understanding trade-offs between terms helped our team make better concessions during talks.

We could see how economic changes might affect contracts over time. This led to stronger agreements that protected everyone from market swings while keeping value fair. Research shows this method helps companies cut supply chain problems by up to 50% through better risk planning.

The change wasn’t just about technology. Our procurement team learned to use these AI tools effectively. Human expertise combined with machine intelligence raised our supplier negotiation game to new levels.

Breakdown of the 40% Cost Savings Achieved

Our AI-powered supplier negotiation initiative showed amazing results with a 40% cost reduction in procurement operations. Let’s get into the key factors that led to these big savings.

Savings from early payment discounts

Early payment discounts became a major source of savings. They made up about 15% of what we saved overall. Our AI system found bills that qualified for early payment discounts. It showed the discount timeframes and possible savings to everyone involved. Our team used this information to speed up approvals for invoices that offered discounts.

Our AI found every possible early payment discount from our suppliers. These discounts usually gave us 2% off if we paid a 30-day invoice within 10 days. This is a big deal as it means that the return was 36% annually – way better than standard investment returns.

The system did more than just spot discount chances. It scheduled payments on its own and got the most savings without anyone stepping in. This automation saved the USD 3 million in missed early payment discounts that usually happens with every USD 1 billion in orders.

Reduced overpricing through AI benchmarking

AI-powered price standards gave us the biggest savings – about 20% of the total 40% reduction. The platform looked at over 2 billion deals and 150,000+ vendor profiles to set fair market prices for everything we bought.

Our procurement team got up-to-the-minute pricing insights that showed when we paid too much. To name just one example, the system found that our competition paid much less for similar software. This gave us solid data to go back and get better rates from the vendor.

The AI kept track of pricing trends and spotted differences between our rates and current market prices. This real-life data helped our negotiators challenge vendors who claimed they needed to raise prices.

Lowered risk premiums via predictive risk scoring

The last 5% of savings came from lower risk premiums through AI-powered predictive analytics. The system gave complete risk scores based on financial stability, delivery performance, and compliance metrics.

We spotted possible supplier risks early and put targeted risk plans in place. This forward-thinking approach let us get better risk premiums from suppliers and insurers.

Analytical risk management in procurement played a vital part here. The AI looked at data from suppliers, market trends, and internal processes to find patterns humans might miss. We could then tell high-risk suppliers from low-risk ones more accurately and avoid the extra “risk premium tax” in pricing.

Ready to see these results in your procurement? Talk to our Expert today to learn how AI-powered supplier negotiation can reshape your costs while deepening your supplier relationships.

Supplier Collaboration and Relationship Gains

AI implementation not only saved costs but also brought remarkable improvements in how we work with suppliers. The technology reshaped basic supplier interactions into strategic partnerships. This created value for everyone throughout the procurement lifecycle.

Faster onboarding through AI validation

AI made our supplier onboarding process much faster by automating document collection, compliance checks, and background verification. The optimized process took just days or hours instead of months. The system checked supplier credentials automatically within seconds. It used global data sources and cross-checked information across multiple databases.

The system’s power to scan and interpret legal documents removed bottlenecks in verification workflows. Our platform extracted vital information from supplier documentation through optical character recognition and natural language processing. This led to faster validation with fewer manual errors. The feature proved valuable for international suppliers who often face complex documentation requirements.

Joint forecasting enabled by shared AI insights

Better onboarding came with unprecedented collaboration through shared demand forecasting. Our platform let us exchange data securely with key suppliers. This created a single view of upcoming needs based on market trends and past patterns.

The system looked at both structured and unstructured data to predict demand. Suppliers could see these predictions through dedicated portals. Such transparency helped both sides arrange production schedules and inventory levels. This prevented stockouts and excess inventory. A retailer who tried a similar approach now shares AI-generated demand predictions with suppliers. Their inventory management improved by a lot.

Increased supplier satisfaction scores

These AI-powered improvements ended up bringing measurable gains in supplier satisfaction. Our supplier survey showed:

-

98% of vendors cited improved communication as a key benefit

-

90% reported positive experiences with AI-assisted negotiations

-

95% noted boosted employee satisfaction with optimized processes

The collaborative effort brought faster supplier payments, clearer expectations, and less administrative work for everyone. We addressed suppliers’ needs better by automating routine communications and offering 24/7 support through AI chatbots. These improvements promoted stronger partnerships based on mutual trust and shared goals. The relationship evolved beyond traditional conflicts toward true strategic collaboration.

Scalability and Future Applications of AI in Procurement

The future of AI in procurement shows great promise for organizations looking to grow their digital capabilities. Procurement teams are building on their early AI wins, and three key areas show exceptional opportunities ahead.

Extending AI to indirect spend categories

AI applications now expand faster beyond direct materials into indirect spend management. Organizations can save about 10% in OPEX across indirect categories through AI-powered spend analytics and optimization. The use of AI tools in indirect procurement—from marketing and facilities to IT and logistics—can lead to savings between 25-30%. Organizations can find savings opportunities that human analysts often overlook by applying machine learning to indirect spend data.

Integrating AI with ERP and SRM platforms

The merger of AI with existing enterprise resource planning (ERP) and supplier relationship management (SRM) systems marks a crucial development in procurement technology. Research shows that procurement teams with integrated AI systems see a 9.9% increase in efficiency and 9.5% improvement in effectiveness. This combination helps teams connect data across previously separate systems and provides better visibility throughout the source-to-pay process.

Organizations should focus on ERP solutions that come with built-in AI capabilities to get the best results. The global market for machine learning technology will grow from USD 21.17 billion in 2022 to USD 209.91 billion by 2029. These numbers highlight why AI-ERP integration matters more than ever.

Using generative AI for contract drafting

Generative AI brings revolutionary possibilities to contract creation and management. It goes beyond simple automation to draft complete contracts, suggest changes, and identify potential risks in contract language. During procurement negotiations, it can create initial contract drafts and recommend the best clauses based on past performance data.

Ready to see how these advanced AI capabilities could reshape your procurement process? Talk to our Expert today to find AI implementation strategies that line up with your supplier negotiation needs.

Schlussfolgerung

Our case study shows how AI-powered supplier negotiation techniques reshaped our procurement operations and led to a 40% reduction in costs. Manual processes used to slow us down, but AI tools changed everything. The combination of NLP-based contract intelligence, predictive analytics for supplier behavior, and automated negotiation bots created a powerful system that produced amazing results.

We used data to segment suppliers and create custom negotiation approaches for each tier. Our team gained new pricing power through immediate market intelligence. The team modeled different contract scenarios to find the best terms and make smart trade-offs.

The cost savings came from three main areas: early payment discounts saved 15%, AI-based price comparisons cut overcharging by 20%, and predictive risk scoring reduced premiums by 5%. Beyond these numbers, we built better supplier relationships. Faster onboarding, shared forecasting, and higher satisfaction scores proved that both sides benefited from AI.

AI’s future in procurement looks bright. We see great potential in expanding to indirect spend, connecting with ERP and SRM platforms, and using generative AI to draft contracts.

Companies still using old negotiation methods are falling behind. AI has proven itself as more than just a way to cut costs – it’s a strategic tool that builds stronger supplier partnerships while saving money. These results make it clear that AI-powered supplier negotiation is the new standard in procurement. This blend of human expertise and machine intelligence achieves what once seemed impossible.

Über den Autor

eMoldino

eMoldino

eMoldino zielt darauf ab, Ihre Fertigungs- und Lieferkettenprozesse zu digitalisieren, zu rationalisieren und zu transformieren. Wir helfen globalen Herstellern, die Unternehmensinnovationen vorantreiben und gleichzeitig die Grundwerte der Zusammenarbeit und Nachhaltigkeit beibehalten wollen. Sprechen Sie mit uns und erfahren Sie mehr →

Hat Ihnen die Lektüre dieses Artikels gefallen?

5 / 5 Auszählung der Stimmen: 2

Entdecken Sie unsere neuesten Beiträge