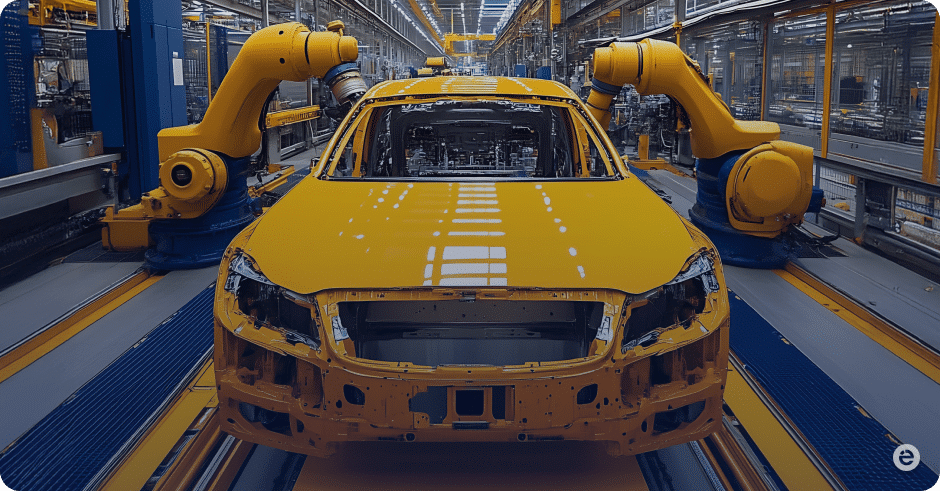

Global OEMs Adopt Real-Time Supplier Management Technology

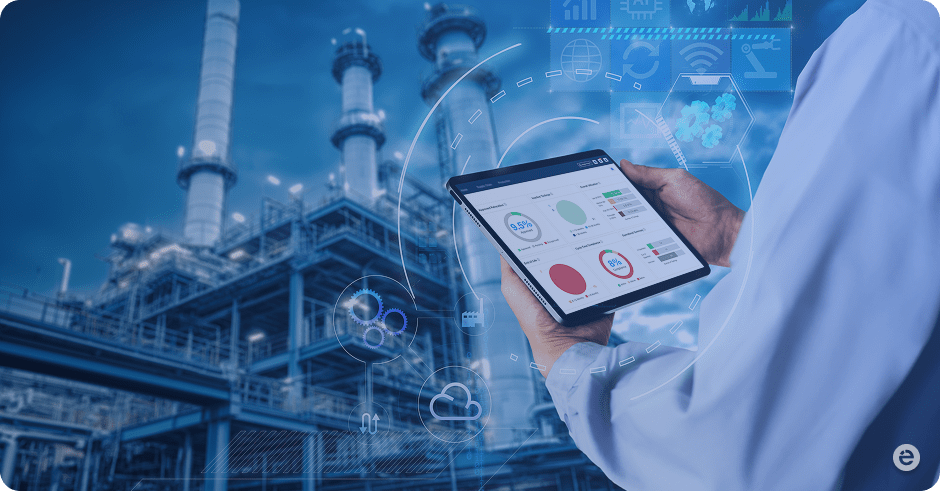

Automotive Global OEMs Adopt Real-Time Supplier Management Technology Published: Aug 6, 2025 Reading time: 3 min Link copied to clipboard! Technology failures in supplier relationship management cause organizations to lose thousands of dollars every minute due to unplanned downtime. Production stops due to unavailable critical parts frustrate everyone. Missing components can triple the time needed […]

Global OEMs Adopt Real-Time Supplier Management Technology Read More »