Our Solution

Outshine your competition with eMoldino’s tried and tested outsourced manufacturing and supply chain solution. Already in use by multiple Global Fortune 500 OEMs, we deliver consistent and value-driven results for your organization.

IoT SENSOR & SOLUTION

Engineered for Accuracy, Consistency, and Reliability

Once installed on your equipment, our sensors capture critical production data in real time. Designed to be tamper-proof and IP64-rated, each sensor can withstand the harshest conditions during production and maintenance. With thousands of sensors globally installed, eMoldino takes pride in offering our proven hardware to Fortune 500 clients worldwide.

Reliability, consistency, and quality are paramount to our customers, and we are committed to delivering a product that not only meets these criteria but also sets new industry standards. We go beyond what is necessary to ensure our clients receive a solution that surpasses expectations.

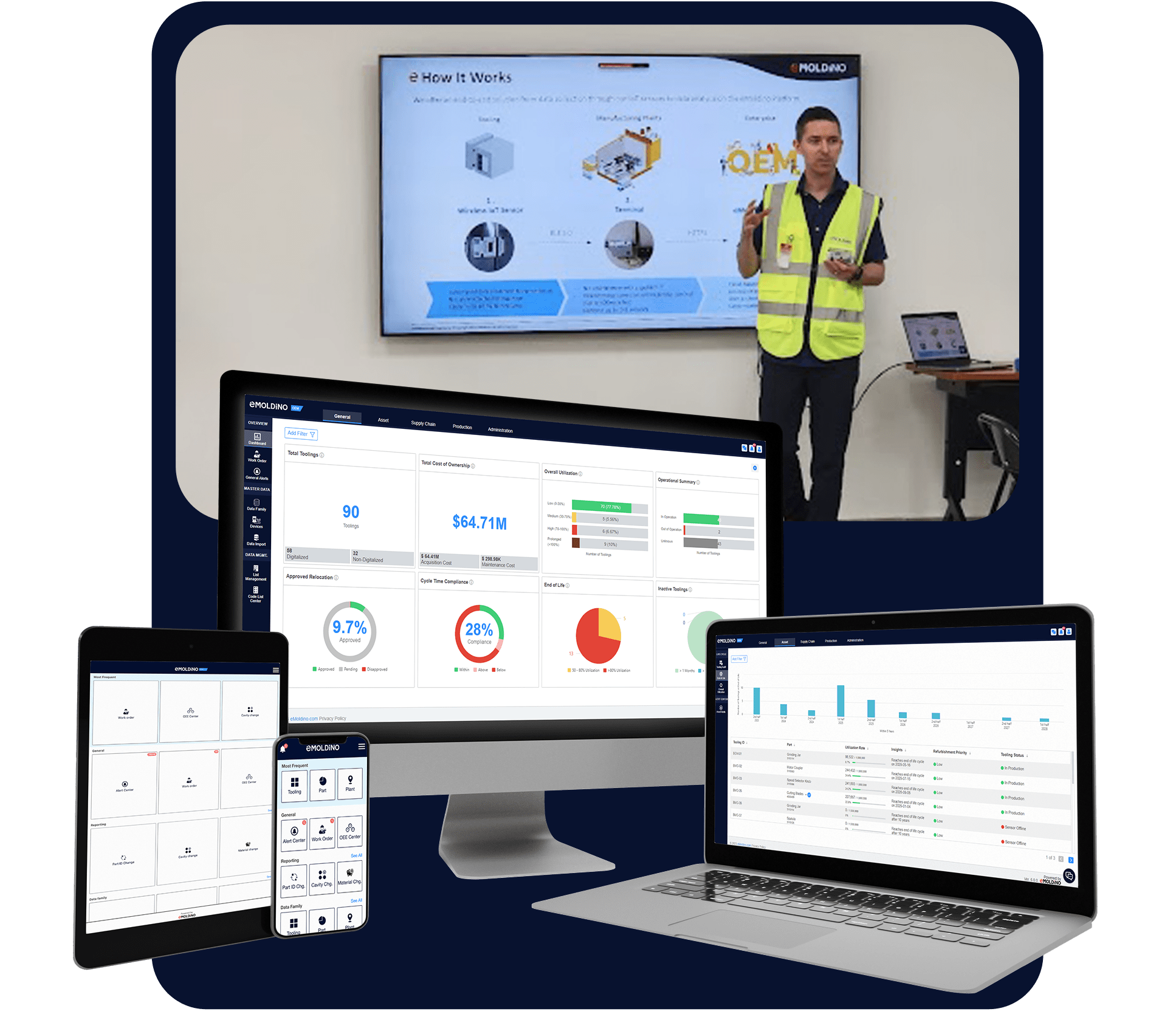

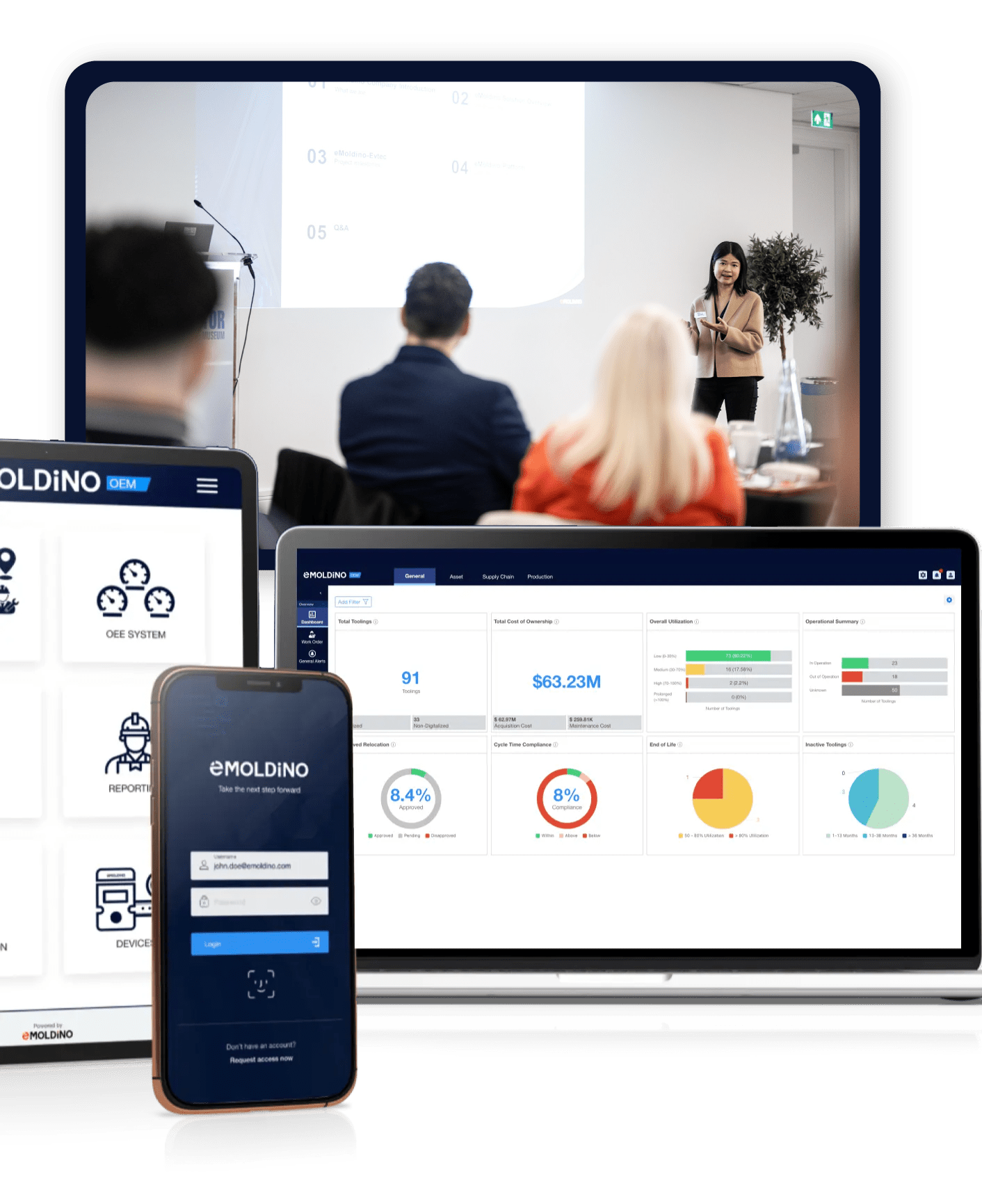

Designed for Visibility & Control

Empower your outsourced manufacturing operations by accessing real-time production data and taking complete control. Our cloud-based solution offers a wide range of applications, providing detailed reports, predictive analytics, and user-friendly controls.

Gain immediate insight through dashboards and alert centers, ensuring you have clear visibility into even the most remotely located assets. Streamline your operations with intuitive graphs, centralized product libraries, and smart work order tools. Experience the power of seamless connectivity and optimize your outsourced manufacturing processes.

How it works

Easy to install & delivering accurate data in real-time!

Data

Capture

Once installed on your tooling, our plug-and-play sensors automatically start to capture all the necessary production data. This information is then transmitted to a central terminal from where it is uploaded into your individual cloud.

Data

Analysis

Our proprietary software churns through all of your production data and delivers it in form of easy to read reports and dashboards, highlighting the most important information, ensuring that you don’t miss out on any potential risk.

Business Execution

Once the data is available in your platform, you’ll receive prescriptive and predictive advice on how to optimize your outsourced manufacturing chains and avoid any potential bottlenecks before they arise.

WATCH it work

Unlocking the Full Potential of Your Outsourced Manufacturing Operations

FEATURE SOLUTION

Tooling Asset Management

Automatically alerts for Preventive Maintenance,

assigns tasks to engineers, and logs each action for a

comprehensive tool history—supporting quality and

timely refurbishment and tooling replacements.

FEATURE SOLUTION

Supply Chain Management

Monitor production speed deviations from approved cycle times and temperature inconsistencies—key

indicators of potential defects.

FEATURE SOLUTION

Production Management

Value Benefits / Use Cases

Asset Management

Tracking tooling inventory, maintenance times, and utilization rates across multiple locations.

Production Management

Monitor status and performance of tooling assets, identify potential production delays or downtime, and optimize resource allocation.

Executive Decision Making

Gain insights into tooling data to make strategic decisions, assess overall production performance, and identify areas for improvement.

Capacity Planning

Keep oversight of product/part capacity across outsourced manufacturing plants and plan your production schedule based on predicted capacity data.

Operational Efficiency

Gain insights into the status of each mold to optimize resource allocation, plan proactive maintenance, and streamline operation.